Description

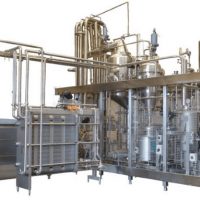

For good extraction performance under delicate thermal conditions, Cold Break treatment limits the temperatures reached to values that generally range between 65 ° C y 73 ° C, to improve preservation of color and flavor . By breaking down the actual enzyme inactivation, the product thus obtained is less viscous than a Hot Break product. Unlike the HB process, in the Cold Break process, the product passes through the exchange pipes without recirculating in the holding pipes, for a more gradual temperature rise and to further minimize juice exposure to thermal shocks .